electrical discharge machining process

It converts electrical discharge into thermal energy that melts or vaporizes excess. In this process an electric spark.

Electrical Discharge Machining Edm Everything You Need To Know

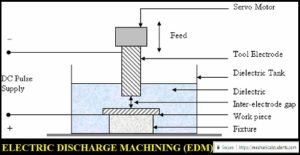

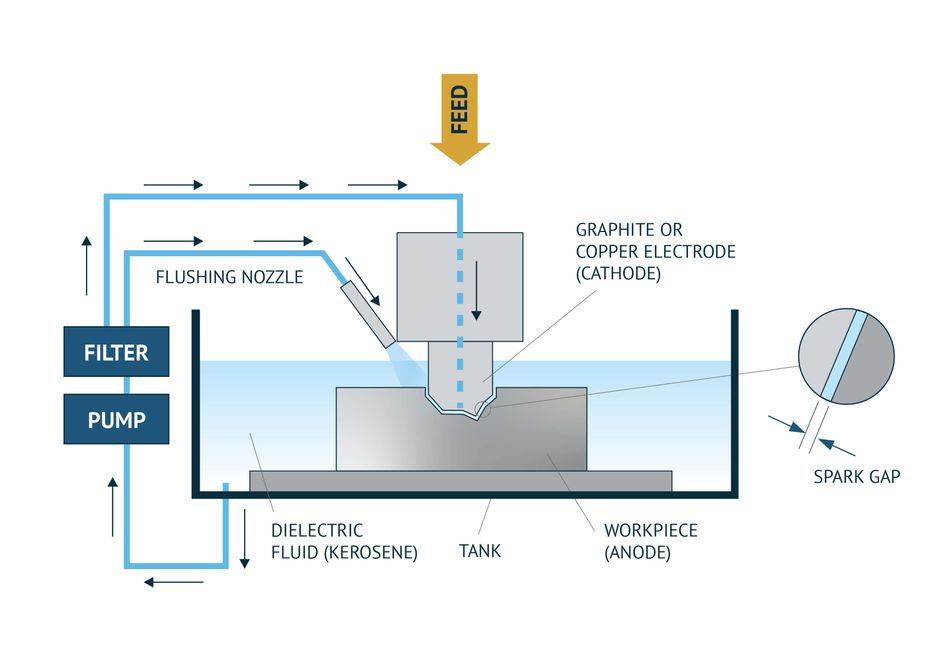

Electric discharge machining is a non-conventional machining process that uses an electric spark to remove metal from the workpiece.

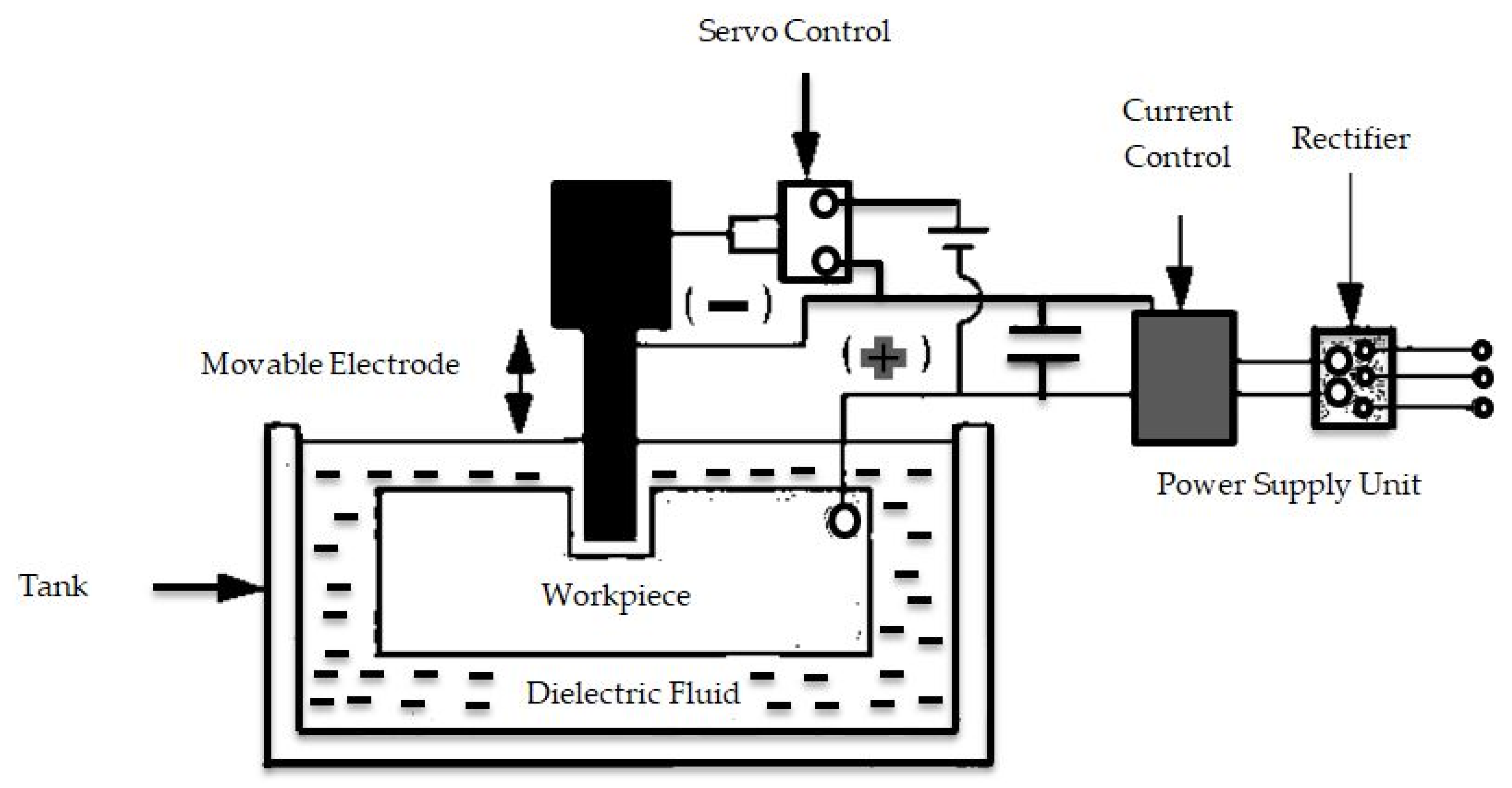

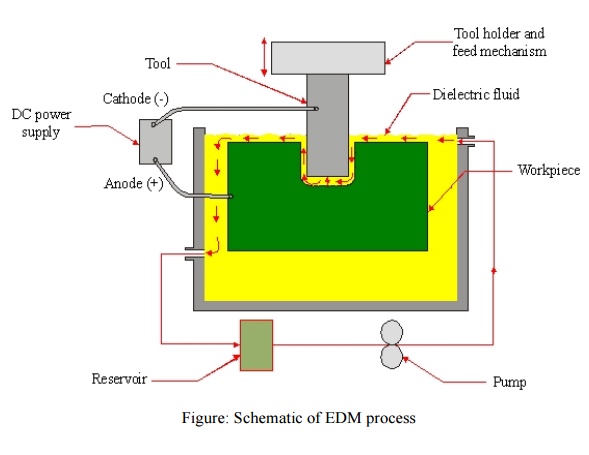

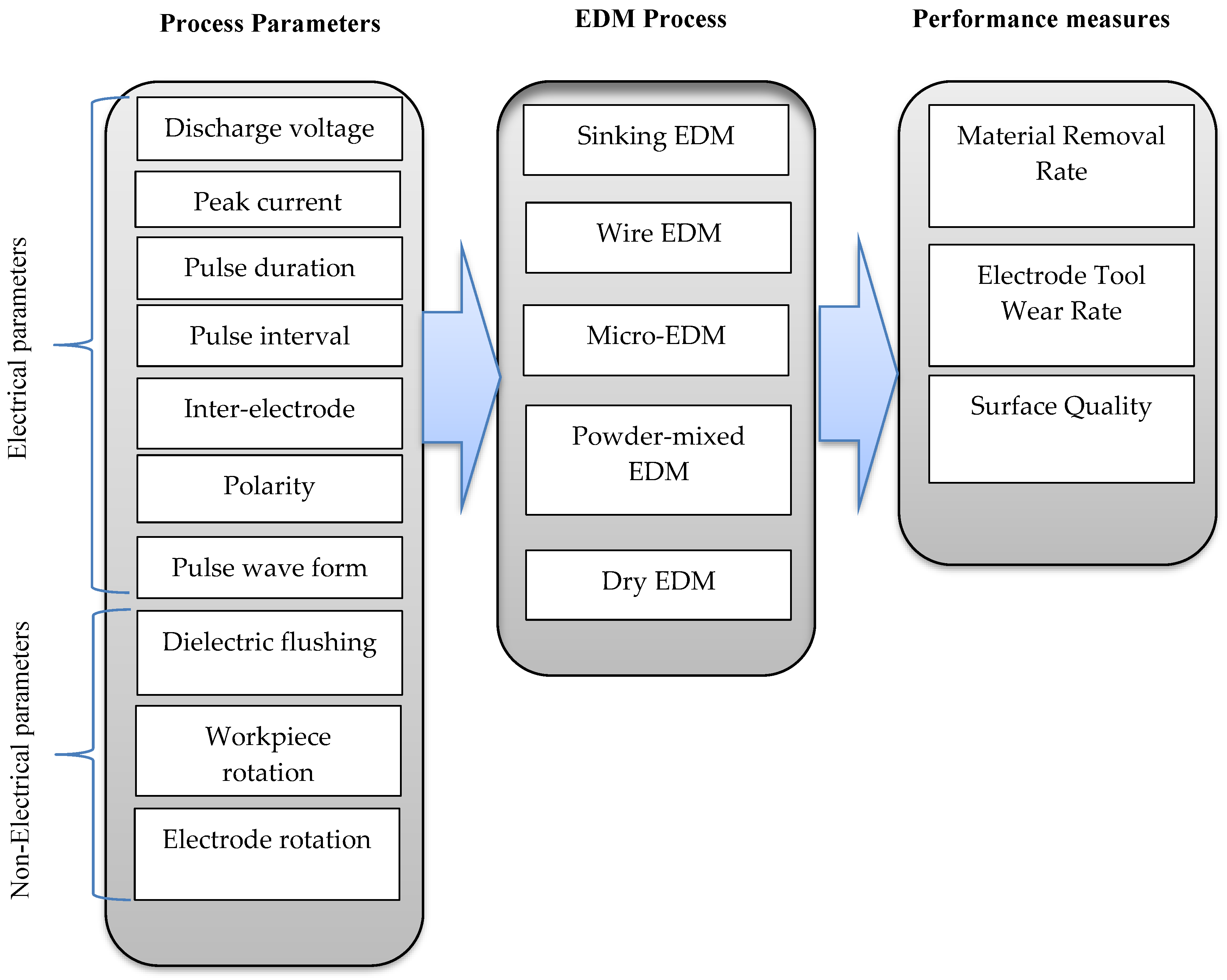

. What is Electrical Discharge Machining. Electrical discharge machining or EDM is a manufacturing process that uses electrical energy to cut through metalalso known as discharge machining or electroerosion. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools.

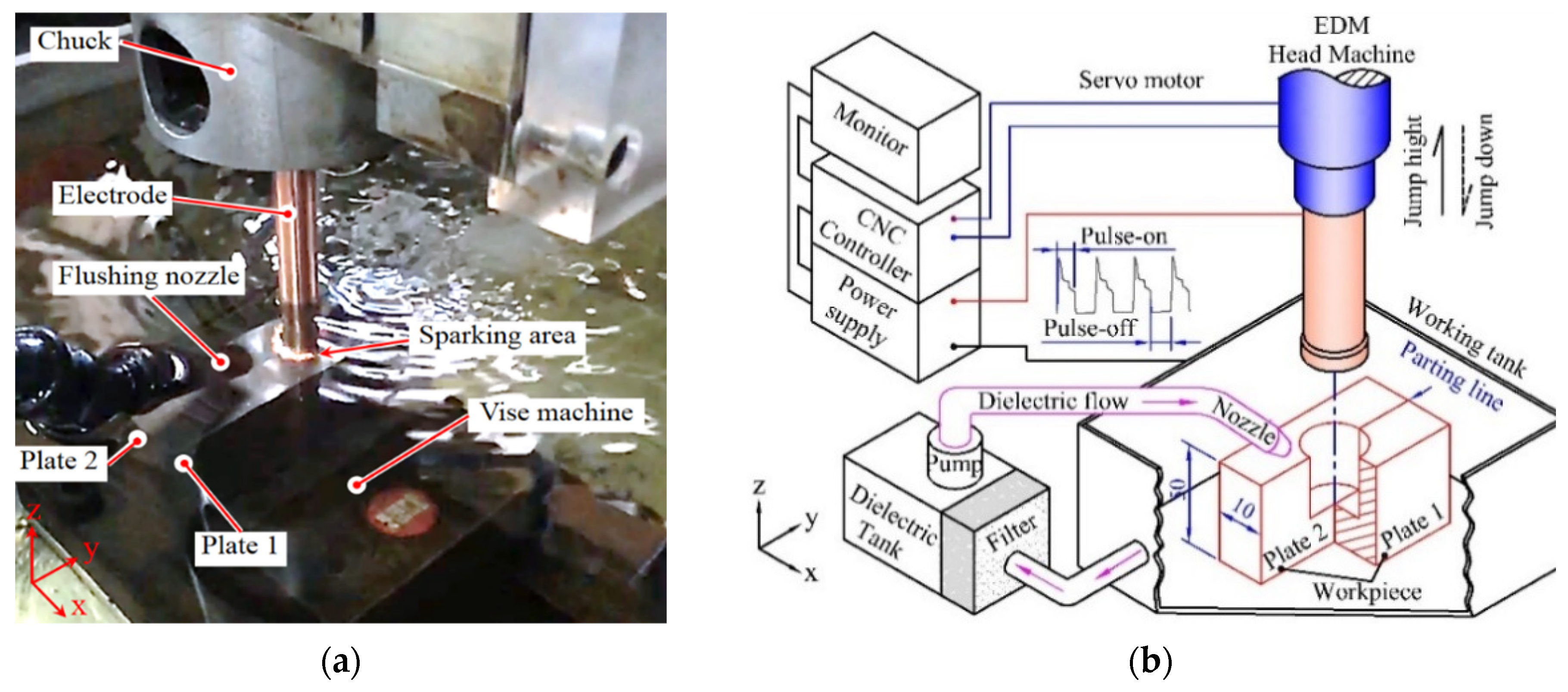

The accumulation of debris between the inter-electrode gap caused by inefficient flushing during the micro-electrical discharge machining micro-EDM process leads to severe. Since products from such alloy materials are. Electrical Discharge Machining EDM is a controlled metal-removal process that is used to remove metal by means of electric spark erosion.

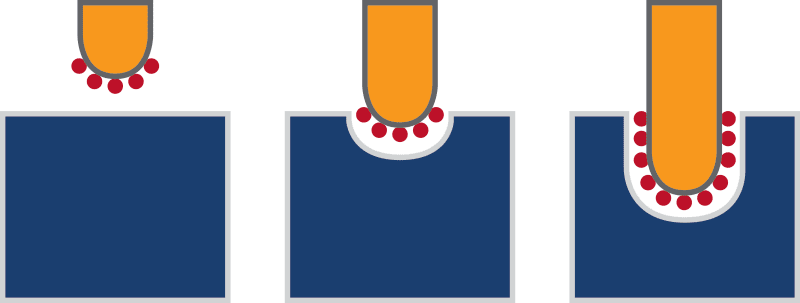

THERMAL ENERGY DISTRIBUTION AND OPTIMIZATION OF PROCESS PARAMETERS DURING ELECTRICAL DISCHARGE MACHINING OF AISI D2 STEEL A THESIS SUBMITTED IN PARTIAL. Wire EDM Sometimes referred to as wire erosion or spark EDM wire EDM is a popular process. In the EDM process a spark causes material of two electrodes tool and workpiece to evaporate and melt in a narrow space filled with dielectric fluid within a few.

With the growth of the manufacturing industry the demand for alloy materials with high hardness toughness and impact strength has increased. To make you understand the Electrical Discharge Machining is a process in which highly sophisticated computer-controlled machines are used to cut a variety of intricate designs in. The performance of electrical discharge machining for drilling holes decreases with machining depth because the conventional flushing and electrode cannot completely.

This is in contrast to the. This process is also named spark erosion machining or spark over initiated discharge machining as the removal of metal occurs due to erosion caused by the electric. The different types of electrical discharge machining include.

Electrical discharge machining is a heat-based subtractive manufacturing process. In this process an electric spark is. It involves the use of a brass wire or.

2 electrodes namely the anode. Electrical Discharge Machining EDM is a non-traditional process of manufacturing that uses thermal energy to remove materials from a partially finished product. Download Citation Analysis of Machining Parameters of Wire Electric Discharge Machining Process on Polysilicon Material The experimental investigation deals with wire.

This process is done by applying high-frequency. Electric discharge machining also known as spark erosion electro-erosion or spark machining is a metal removal process that uses an. In the unconventional process of electrical discharge machining or EDM material is removed from a workpiece using thermal energyEDM doesnt require mechanical force to.

Electrical Discharge Machining EDM is a controlled metal-removal process that is used to remove metal by means of electric spark erosion. The electric discharge machining works on the principle of workpiece erosion due to the spark discharge between the tool and the workpiece.

Electrical Discharge Machining Construction Application Pros And Cons

Electrical Discharge Machining Edm Process Explained Fractory

What Is Electrical Discharge Machining Edm Get It Made

Applied Sciences Free Full Text Improving Machining Performance For Deep Hole Drilling In The Electrical Discharge Machining Process Using A Step Cylindrical Electrode Html

What Is Wire Edm Electrical Discharge Machining Xact

Electric Discharge Machining Advantages Disadvantages

Figure 3 2 From Chapter 2 Literature Review 2 1 Introduction History Of Electrical Discharge Machine Edm 2 3 Electrical Discharge Machine Edm 2 4 Electric Discharge Machine Edm Process Electric Discharge Machine Edm Capabilities 3 2

Current Research Development In Dry Electric Discharge Machining Dedm Review Paper Semantic Scholar

Micromachines Free Full Text Recent Advances And Perceptive Insights Into Powder Mixed Dielectric Fluid Of Edm

Electrical Discharge Machining Ppt Video Online Download

How An Electrical Discharge Machining Works Engineer S Academy Youtube

Electrical Discharge Machining Edm

Wire Edm Wire Electro Discharge Machining Engineeringclicks

Gate Ese Electrical Discharge Machining In Hindi Offered By Unacademy

What Is Wire Edm Electrical Discharge Machining Xact

Materials Free Full Text Advanced Electric Discharge Machining Of Stainless Steels Assessment Of The State Of The Art Gaps And Future Prospect Html

Electric Discharge Machining Process Animation How Electric Discharge Maching Works Youtube

Electrical Discharge Machining An Overview Sciencedirect Topics